-

Your SAP ERP

Get what you want. Choose your SAP ERP.

- Products

-

Rapid Apps

Executive AppsUser AppsIT Apps

-

Services

-

Support

Liquid UI CommunityLIQUID UI DOCUMENTATIONLIQUID UI TOOLS

- Resources

- Company

- Free Trial

Second-largest food production company

Leading Packaged Food Company | Top Athletic Shoes and Apparel Company | Second Largest Food Production Company | How to Get Started?

Challenges:

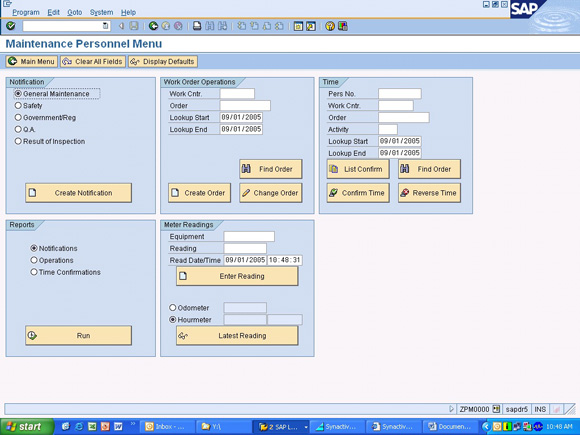

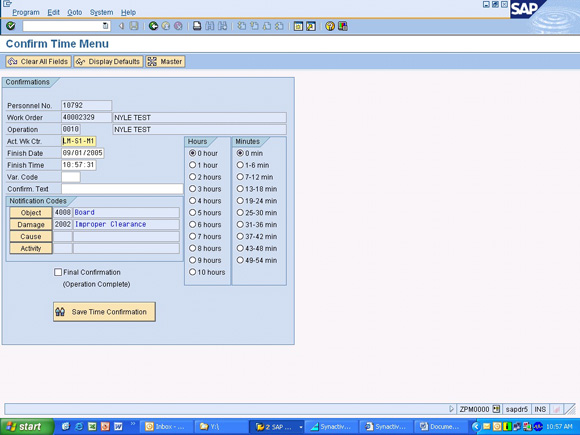

- Entering notifications, issuance of parts, and labor odometer readings was laborious

- Vehicle work orders confusing and time consuming for mechanics

- Poor training resulting in bad data quality

- Delayed vehicle repairs causing delays in shipments to customers

Solution:

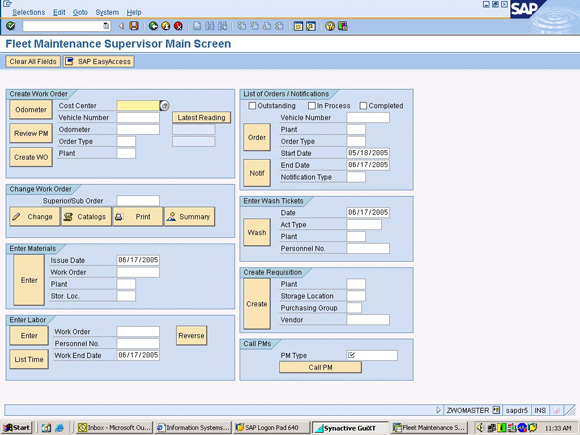

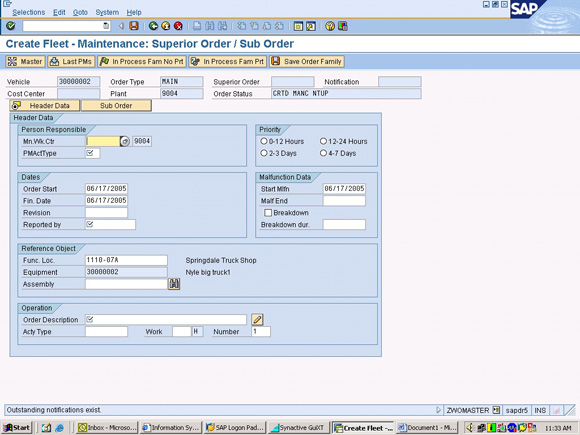

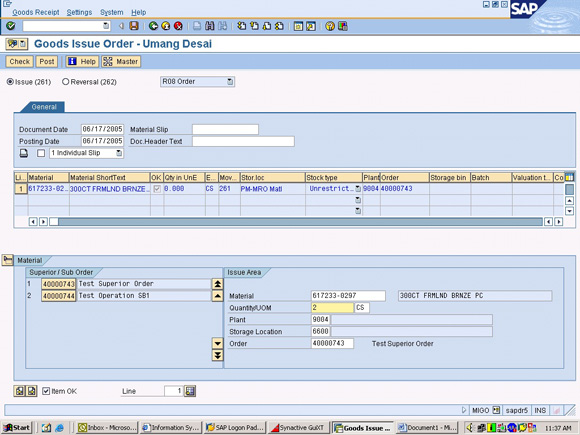

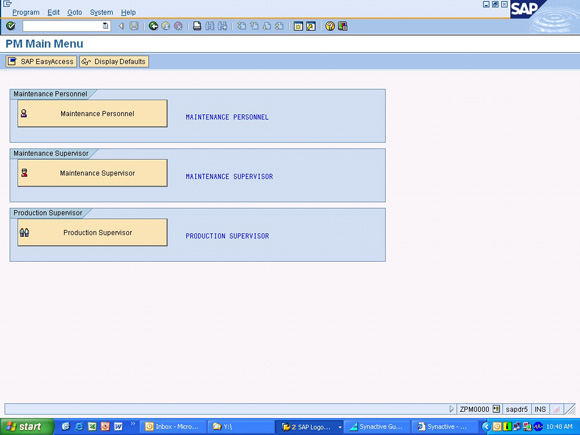

- Consolidate notifications, work orders, issuance of parts, odometer readings and time confirmations all on ONE screen with different interfaces based on different roles

- Create parts warranty alerts prior to expiration

- Simplify process to ensure equipment receives correct PM's at the right time

- Ability to enter wash tickets

Results:

- Streamlined vehicle repair process resulting in $1M savings in just the warranty process alone

- Complete visibility of entire fleet's PM schedule resulting in PM's managed more effectively, decreasing breakdowns while increasing miles run.

- Overall great results and user acceptance prompted them to expand GuiXT in MM and PM to over 8,000 users

- Drive Best Practices with GuiXT by standardizing using variants to take the guesswork out of the user's hands