Moving closer to a digital future, more SAP businesses around the world are shifting their focus away from legacy applications and toward digital solutions for optimizing their business processes. However, it is critical for the warehousing industry, which operates in increasingly volatile environments, worsened by the recent global health crisis. Maintaining the durability and adaptability of your warehouse with the best partner is the best approach for dealing with unforeseen challenges in the global supply chain.

Additionally, the top-tier SAP warehouse management functionalities of the ecosystem were expanded by the release of SAP EWM solutions on S/4HANA in the cloud. Customers who want to operate their warehouses in the cloud now have access to a wide range of SAP native business applications for an overall lean governance curve.

Mobile technology is essential to the success of seamless digital solution integration. Mobile access to SAP's warehouse solutions for warehouse and field workers supports all warehouse types, maintenance, repairs, operations, raw materials, and finished goods.

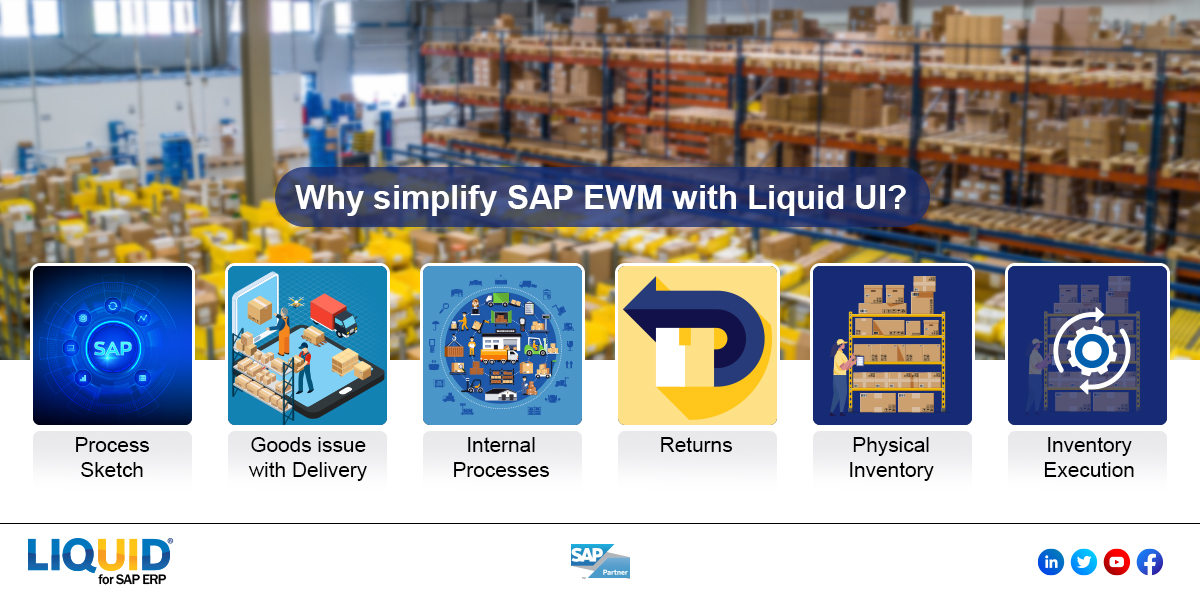

Impact of Liquid UI S/4HANA Transformation on the SAP Warehouse Workflow

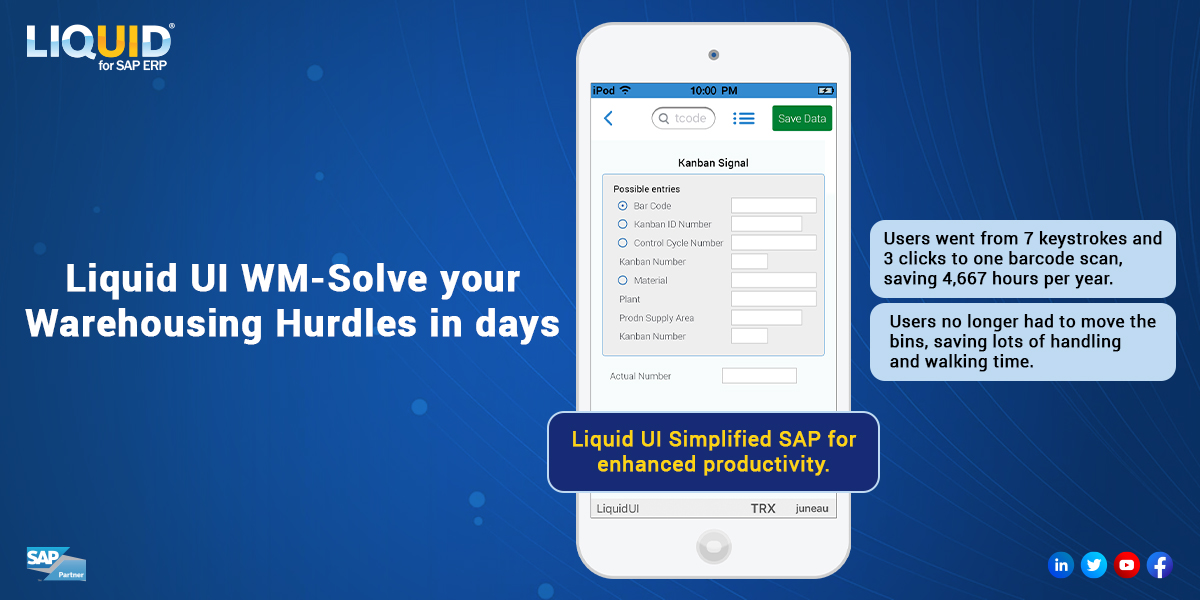

It is a known fact that the warehouse workforce needs powerful mobile applications, ideally on handheld devices, to speed up their hands-on responses to everyday challenges. To overcome the above challenges, Liquid UI mobile apps have significantly improved the efficiency with which the enterprise's transformative operations are carried out. Liquid UI apps have features like barcode scanning, security locks, mobile printing, etc. that make them both aesthetically pleasing and useful.

Key features of Liquid UI EWM Solutions

Liquid UI SAP EWM solutions empower your warehouse personnel, from mobilizing solutions to planning processes to managing inventory to achieving regulatory compliance to laying down a scalable foundation for future growth, in just days.

Liquid UI offers several tools and application programming interfaces for developing high-performance solutions. Liquid UI for Handheld Scanguns is essentially a barcode scanning solution that supports various warehouse work processes locally. They provide a user-friendly interface that requires little to no training, thereby empowering frontline workers. It provides real-time, accurate access to SAP EWM data.

Users can accomplish a variety of tasks using the application, including

- Secure packing of goods

- Safe receiving and put-away

- Easy packaging

- Automated scrapping from inventory books

- Efficient bin-to-bin transfer

- Effective handling of ad-hoc goods issues

- Inventory counting on the go

Customers who use Liquid UI applications will benefit from hands-free functionality, quick barcode scanning in a native SAP environment, and minimal user training. In addition, the application works uninterrupted in offline modes and offers data isolation for device sharing. The application allows the use of device standard features to their full potential. Moreover, it is easily implementable in no time.

Increase Productivity and Inventory Accuracy in Warehouse Operations

Liquid UI mobile apps are developed to boost warehouse efficiency and give front-line maintenance personnel the best support possible. Liquid UI digitizes all warehouse processes, allowing for paperless operations and ensuring technicians receive the correct product at the correct time. Integrating seamlessly with work orders, our mobile solutions—Liquid UI for Android/iOS ensure maximum technician productivity and a truly integrated supply chain.

Key Features of Liquid UI Mobile Solutions:

- Real-Time Automation and Digitization of All Physical Inventory Movements

- Use smartphones or tablets equipped with OCR, cameras, and rugged barcode and RFID scanners for IOS and Android devices -

- Stock Lookup

- Receiving and Storage

- Issues with Goods

- Order Picking

- Parts Monitoring

- Cycle Counting

- Quality Assurance

- Safety Checks

- Cross-docking

- Traceability

The Only Data Capture Solution your warehouse will require

- Real-time integration of your warehouse workers with SAP

- Automate all inventory movements, both inbound and outbound.

- Manage your warehouse operations with an auto-identification and data-capture solution that is simple, intuitive, and agile.

- Run connected or detached

- Capture all warehouse processes, from goods receipt to goods issue, with automation.

- Real-time, app-based Goods Receiving and Distribution

- Real-time tracking requires physical movements to be coordinated with SAP updates.

- Errors in the manual entry are eliminated.

- Error-free transaction processing

- Pick, Putaway, and Create Shipment Documents

Directed Picking

- Productivity increased by 70%.

- Improve the maturity of the picking process by eliminating paper-based picking proposals.

- Pick in the same order as the material layout to reduce travel distance.

- Use dynamic and app-based directed picking strategies such as FIFO, LIFO, shelf life, expiration date, and so on.

- Increased throughput and shorter cycle times

Real-Time Order Status in SAP

A paper-based process causes a lag between physical movement and SAP updates. Real-time updates to SAP mean that the order's exact status is visible and can be shared with the customer.

- Visibility of Order to Receipt

- Visibility within the four walls

- Customer visibility from the warehouse

Additional features include:

- Easily configure operational dashboards to track all warehouse activities.

- Supervisors and managers can monitor and control operations even when they are not in the warehouse.

- Timeline Line Chart depicting the historical time required to complete goods receipts, goods issues, and other tasks.

- Displays available Cycle Count documents, the number of materials planned, and the number of materials counted versus pending.

Combination Scanning of 2D-Barcodes

A combination scan is a programmable feature that enables Auto Identification and Data Capture with a single scan of a 2D barcode. Increase the speed of your inbound and outbound processing by capturing multiple data fields at the same time.

- Using a single trigger from the scanner device, read multiple values from the barcode and populate the data in the application's respective fields.

- One barcode scanner reads the PO, line item, material, batch serial number, and so on.

- Scan combination barcodes both online and offline.

Anywhere Barcode Label Printing

The mobile printing capabilities of connected Inventory Management improve front-line worker efficiency, reduce trips across the warehouse, and boost morale. Create customized forms and labels that can be printed at the point of application, accelerating the Receiving, Movement, Picking, Packing, and issuing processes.

Digital Cycle Counting in Minutes

Allows warehouse employees to perform digital cycle counts using a handheld device, removing the need for manually recorded counts on paper and system updates.

- Each scan automatically increments the quantity count.

- Document counting by blind count or physical inventory.

- Wall-to-wall, cycle, and ad-hoc counts are all possible.

Proof of Delivery

A Proof of Delivery (POD) is a signed delivery note from the customer that confirms the actual quantity delivered and is then used to generate the invoice. The customer can sign the electronic delivery note directly on his or her smartphone, eliminating the need for paper and creating an electronic Proof of Delivery (ePOD).

- Capture the customer's signature and the date/time of delivery electronically, and the order status is immediately updated.

- Reduce delivery paperwork and avoid lost paper PODs, which can cause customer invoicing to be delayed and working capital to be depleted.

- Signatures are permanently attached to the proof of delivery document and cannot be lost.

- Increase the accuracy of your invoices and your customer service.

Are you ready to digitize your inventory and warehouse operations? Request a demo to learn more about our Liquid UI SAP EWM solutions, which include barcode scanning, GPS tracking, Mobile Printing, and other advanced features.

With Liquid UI Mobile Solutions, you can:

- Eliminate Paper Work 100%, automate and digitize SAP processes to reduce paperwork

- Increase Productivity by 70%, Increased cycle counts, and Receiving & Back-order Reporting

- Increase Inventory Accuracy by 50%, Liquid UI’s real-time data collection and mobility visibility

- Reduce Cost by 59%, Reduce inventory carrying costs with improved visibility