-

Your SAP ERP

Get what you want. Choose your SAP ERP.

- Products

-

Rapid Apps

Executive AppsUser AppsIT Apps

-

Services

-

Support

Liquid UI CommunityLIQUID UI DOCUMENTATIONLIQUID UI TOOLS

- Resources

- Company

- Free Trial

CHEMICALS

SAP Warehouse Management

In warehouse management, different events get created in the supply chain for each piece of equipment that comes from the plant. Events include: receiving equipment; moving equipment to another location; and releasing equipment from the warehouse. Events are created in hierarchical order and they are executed sequentially. However, if a failure occurs, then the rest of the event execution sequence stops.

Equipment and stations are considered master data in SCM. Stations are formed by four areas: site, yards, tracks, and spots. Spots are dependent on tracks, tracks are dependent on yards, and yards exist in a particular site. Equipment moves between these stations by a rail system in SCM.

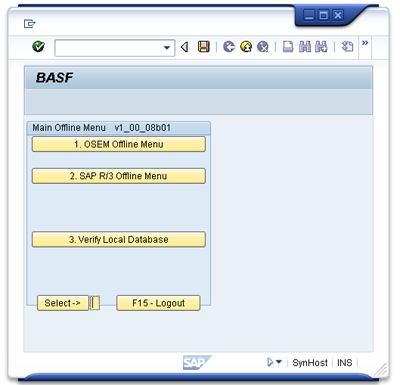

After Liquid UI Offline is implemented operators are able to manage transactions in two different systems and synchronize data with either system when a connection becomes available.

Challenge

In an SAP Warehouse Management transaction, there is no environment to record and consolidate all the events happening during the day in an efficient way. Manual corrections are done for dependent events, for which there is no log mechanism. There is no integration between Supply Chain Management and the Sales and Distribution System.

Solution

Synactive's Liquid UI Offline Solution records all SCM events and has them transferred to online systems immediately. Offline is installed in RF Guns and helps operators to manage each event clearly. Operators can also view each logged error in the mobile device and post data successfully from one specific location.

Liquid UI Offline's benefits can be seen in the integration of Supply Chain Management with Sales and Distribution. Operators manage transactions in two different systems from a single device and are able to synchronize data with either systems at any given time, when a wireless connection becomes available.

Get more details about Efficient SAP WM